Propane Safety

Amano Pioneer Eclipse Corporation has been producing the industry’s safest propane powered floor care machines for over 45 years. We were the first to introduce Safe-Fill cylinders, catalyzed mufflers, emissions monitoring systems, and proprietary carburetion.

Some key points that separate us from our competition include:

- Proprietary carburetion is configured as a lean-burn system to reduce CO output

- 3-way catalytic muffler to reduce not only CO, but also NOx and HC

- Fuel metering optimized for each machine

- Cylinder head modifications for improved combustion

- Re-gapped spark plugs that are optimized for propane ignition

- Safe-Fill cylinders equipped with an over-fill prevention device

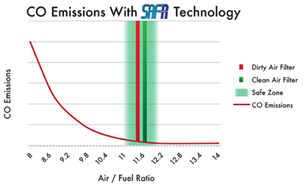

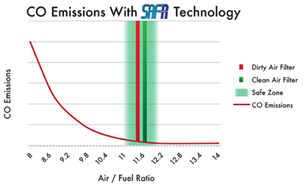

- SAFR™ Technology keeps a Steady Air Fuel Ratio no matter the air filter condition

- EcoSense basic emissions monitoring system available on 400, 420, & 450 series models

- SafeSense enhanced emissions monitoring system available on 440 series models

- SafeStop shuts down machine if improper propane cylinder use is detected

- Operator presence shut-down available on 440 series models

- Both online and classroom courses for propane machine certification

The patent pending SafeStop feature detects improper propane cylinder use, such as overfilled tanks or the use of a liquid-draw tank rather than a vapor-draw tank. If improper use is detected, SafeStop automatically shuts down the machine. This reduces the risk of the most common source of fire hazard when it comes to propane cylinder use on floor machines: overfilled or liquid-draw cylinders. This technology also reduces the possibility of elevated emissions, fuel system/engine/catalyst damage and the chance of a cylinder venting propane inside a building. SafeStop is available as an option on propane burnishers and strippers and comes standard on concrete machines.

The most common occurrence for increased Carbon Monoxide (CO) output from an engine is a dirty air filter. A dirty air filter restricts air flow, which causes the air-fuel mixture to richen, which then results in increased CO. The SAFR (which stands for Steady Air Fuel Ratio) Technology system monitors the pressure between the air filter and the carburetor. As the air filter becomes dirty, the pressure decreases. With SAFR™ technology, this change in pressure results in a reduction in fuel delivered to the engine. The net result is a Steady Air Fuel Ratio no matter the air filter condition. We feel this technology is so important that it will be added to ALL new Pioneer Eclipse propane machines at no additional cost. Regardless of your application or model preference, you can rest assured your Pioneer Eclipse propane machine will be equipped with SAFR technology.